A Step-by-Step Guide to a Traditional Clay Oven

You May Also Like

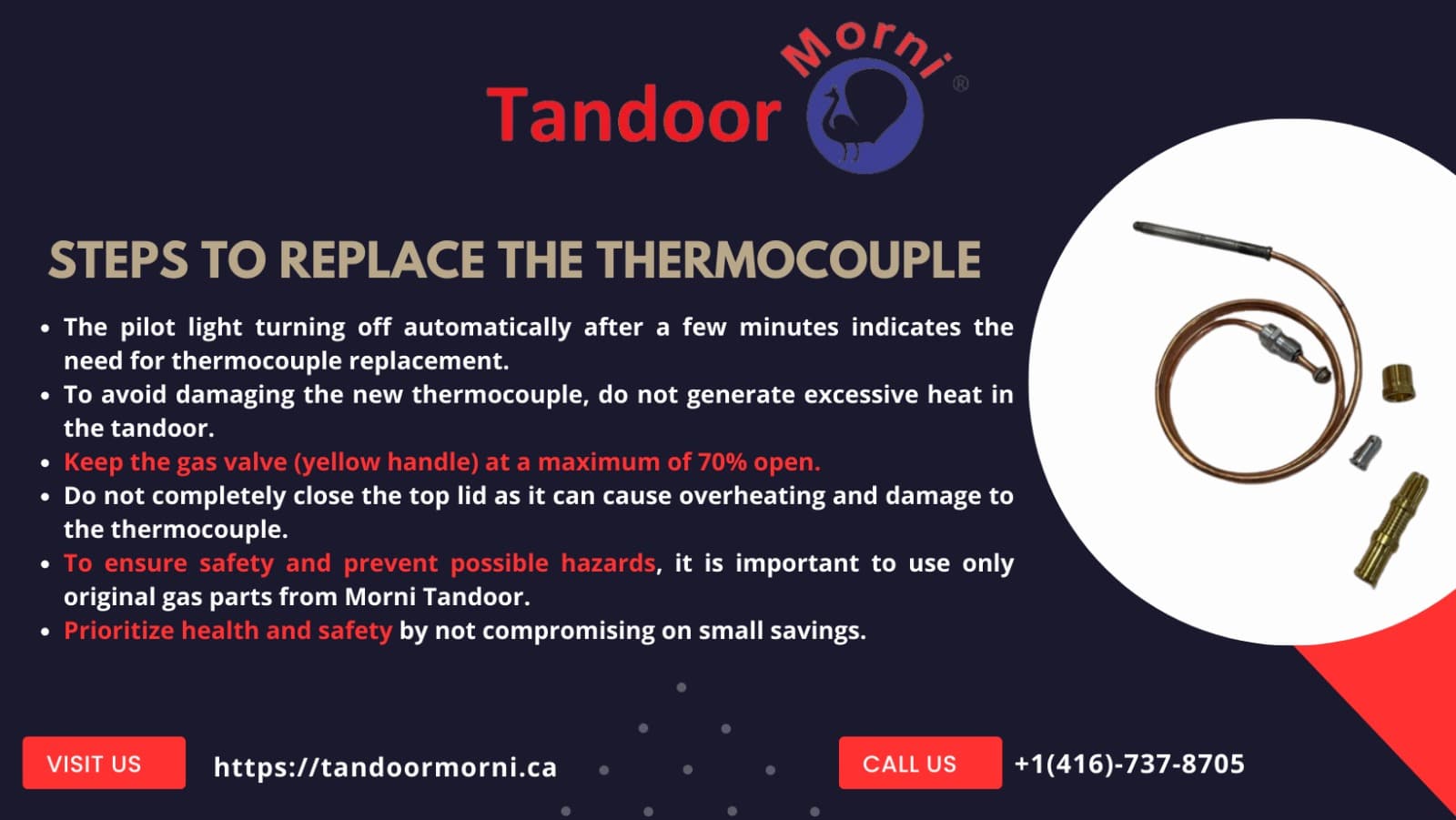

Replacing the thermocouple in a Morni Tandoor oven

📺 INSTRUCTION Are you experiencing 😵💫 issues with your Tandoori Clay Oven's pilot light constantly turning off 💡 ? If so, you might need to replace the thermocouple. 👀 👀 👀 👀 👀 What is a thermocouple, you might ask? It's a safety device that senses the heat of the pilot light and signals the gas valve to release gas…

Easter turkey in a Tandoor oven

To make Easter turkey in a Morni Tandoor Oven T02, you will need: The sun rises on Easter morning, and the air is filled with the tantalizing aroma of roasting turkey. Families across the land eagerly await the arrival of the centerpiece of their Easter feast. But little do they know, some are about to…

Curing a Clay Pot For Tandoor : A Guide

https://youtu.be/xY4bCW3hRsg Learn how to properly cure a new clay pot for optimal cooking results with these easy steps. Make the most out of your first time use with our expert tips! Extend the life of your tandoor by preparing its clay portion before first use. Maximize the performance of your tandoor with this essential clay-curing…